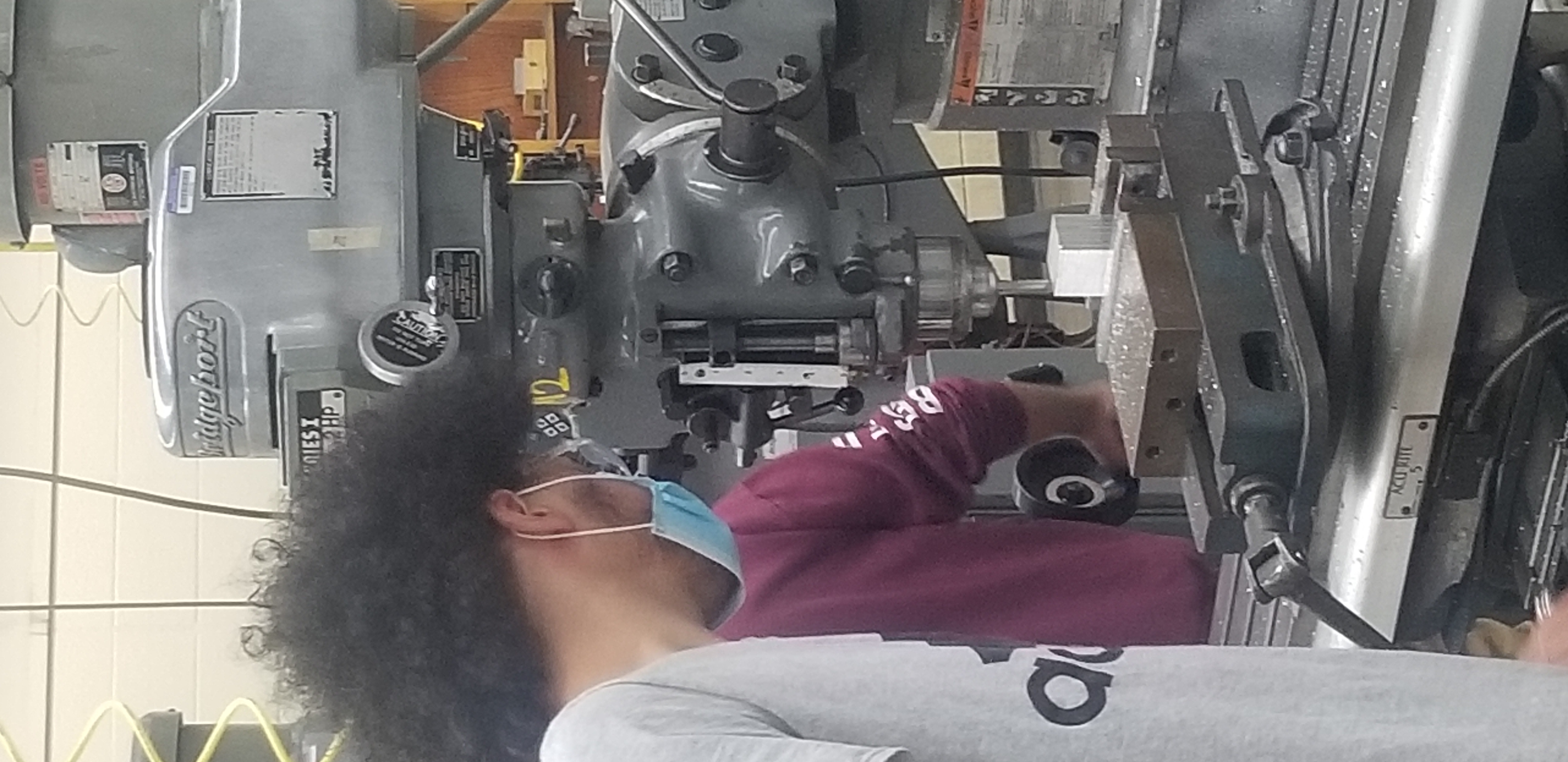

Precision Machining

Precision Machining at a Glance

Machinists create something tangible and practical with blocks of raw materials, their specifications and the machines to bring their ideas alive. These students will learn how to read and understand design files, set up machine tools, operate manual and automatic CNC machines, machine cutting, how to mill, drill, and shape parts, polish and present finished parts, measure, examine and test products, learn customer service skills, and how to customize parts.

Introduction to Design Processes

Introduction to Design Processes is a course that introduces all ETE career pathways and it focuses on creative problem solving in developing, testing, communicating, and presenting post-evaluation of products.

Available to: Grades 9-12

Taught By: Mr. Ott

Requires: None

Principles of Precision Machining

Principles of Precision Machining will provide students with a basic understanding of the processes used to produce industrial goods

Available to: Grades 10-12

Taught By: Mr. Harvey

Requires: None

Precision Machine Fundamentals

Precision Machining Fundamentals will build a foundation in conventional milling and turning.

Advanced Precision Machine

Advanced Precision Machining will build upon the Turning and Milling processes learned in Precision Machining Fundamentals and will build a foundation in abrasive process machines.

Available to: Grades 11-12

Taught By: Mr. Harvey

Requires: (1) Principles of Precision Machining

Precision Machining Capstone

Precision Machining Capstone is an in-depth study of skills learned in prior courses, with a stronger focus on CNC setup/operation/ programming. This class requires an instructor recommendation.

Available to: Grade 12

Taught By: Mr. Harvey

Requires: (1) Principles of Precision Machining; (2) Precision Machine Fundamentals; (3) Advanced Precision Machining

Certifications

National Institute for Metalworking Skills